IMCA Integrated control drive Goniometers

Feinixs develope IMC series products include Linear, Vertical, Rotary, and Inclination, integrating Feinixs innovative technology over the past decade. These products continue Feinixs consistent design concept, pursuing miniaturization, micro-movement, and aesthetics, while combining Feinixs rich experience in displacement stage design, assembly, and control to provide users with a more convenient and efficient user experience. The products use an integrated design of drive and control, simplifying wiring work; using closed-loop motor drive and multi-turn absolute value encoders, they have the characteristics of high precision, fast response, stability, and reliability, without worrying about power-off position changes; supporting multi-axis networking to achieve centralized control; and providing customization services for both software and hardware to meet individualized needs.

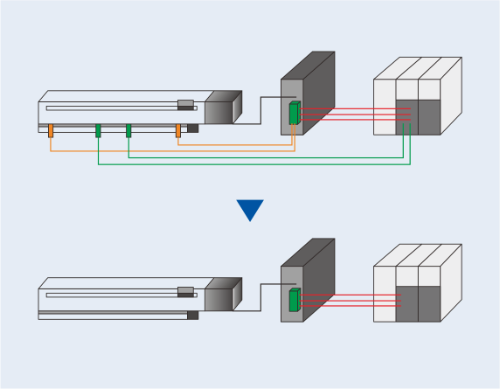

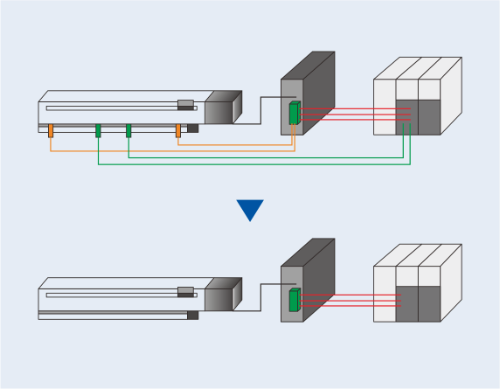

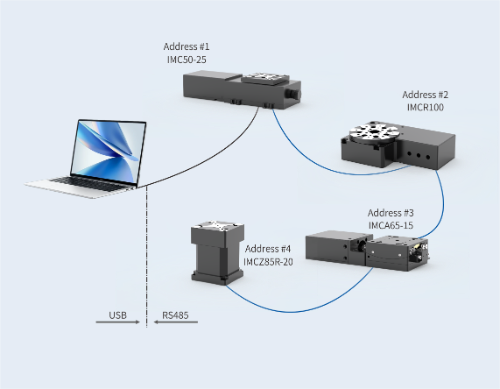

The IMC series has a built-in high-performance controller that simplifies cabling and can be controlled from a PC by simply connecting power and communication cables. Suitable for applications with limited volume, regardless of the placement of the large control box. Improve work efficiency and save space.

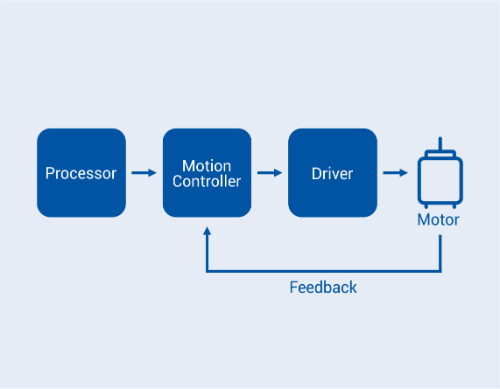

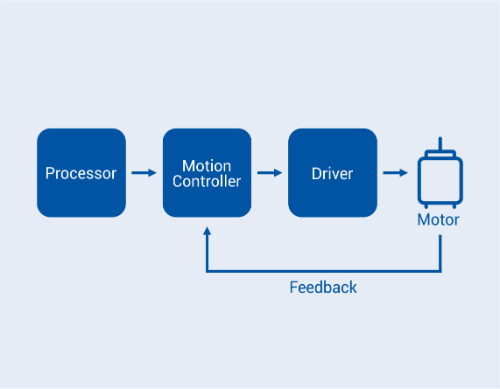

IMC series products are driven by high-quality closed-loop stepper motors, which have the advantages of high precision, high performance, automatic adjustment of winding current, fast response and high overload capability. Provide stable and reliable driving solutions to meet a variety of application requirements.

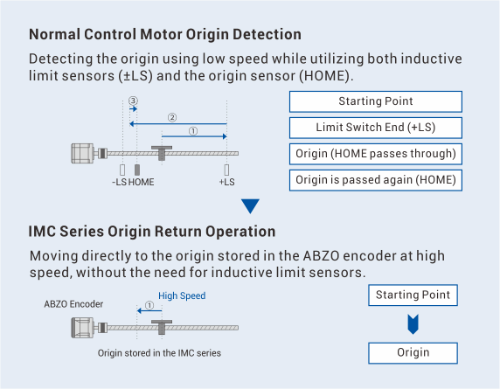

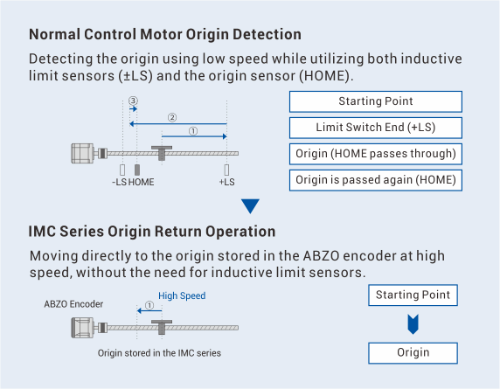

IMC series products use multi-turn absolute encoders to ensure that the exact position of the stages is always known when communication is successful. Even if the power is off, there is no need to worry about position changes, Do not need to find the zero point to establish a coordinate system. And have a high work efficiency.

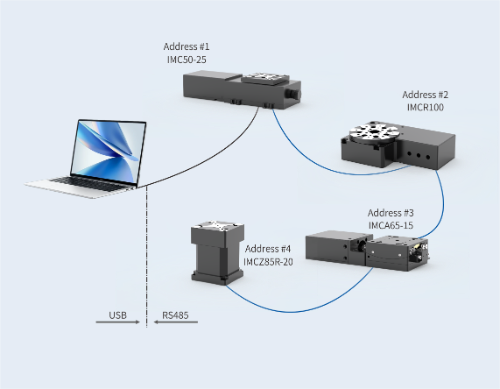

IMC series products use the standard Modbus protocol for control, and the multi-axis stages can realize centralized network control through 485 communication. Simplify the operation process, provide convenient control mode, and meet the needs of multi-axis linkage control.

In addition to standard products, the IMC series also provides deep customization services, which can customize the product structure and software functions according to customer needs, providing customers with a comprehensive solution. Professional customization to meet individual needs.

APPLICATION FIELDS

Optical Microscopy 、 Semiconductor Inspection 、 Biomedical Engineering 、 Fiber Optic Alignment 、 Precision Machining 、 Automated Testing 、 ScientificResearch

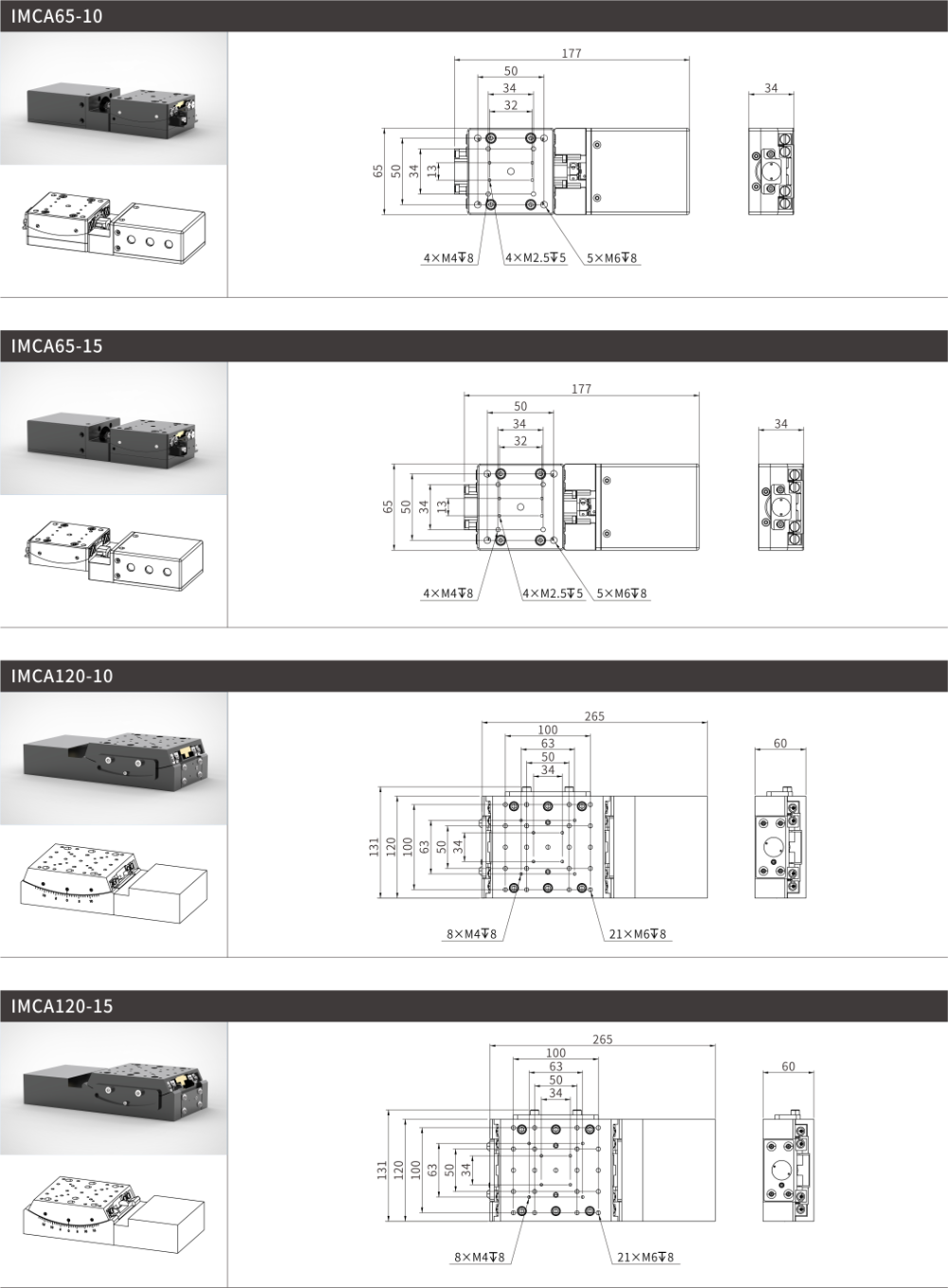

Motorized Translation Stage

Motorized Translation Stage